Food packaging does far more than catch a shopper’s eye. It plays a critical role in maintaining food safety. From preventing contamination and leakage to preserving freshness and extending shelf life, packaging is a key component of food protection.

To safeguard public health and consumer rights, food packaging must comply with strict safety regulations. Different countries enforce unique sets of legal requirements through their governing authorities. In the US, the Food and Drug Administration (FDA) oversees these crucial standards.

In this article, we’ll break down the FDA’s regulations for food packaging and highlight key industry standards that help ensure safety, quality, and compliance across the supply chain.

What is the FDA?

The Food and Drug Administration (FDA) is a U.S. federal agency under the Department of Health and Human Services. Its core mission is to protect public health by regulating and overseeing the safety of food, drugs, medical devices, and related products, including substances used in food packaging.

When it comes to packaging, the FDA ensures that materials intended to come into contact with food meet strict safety standards. This includes preventing harmful chemicals from migrating into food products. These aren’t optional guidelines or best practices — they are mandatory legal requirements that both packaging manufacturers and food processing companies must follow.

The FDA also holds enforcement authority, meaning it can take legal action against companies that fail to comply with food packaging safety regulations.

What does the FDA regulate?

While the FDA plays a vital role in ensuring food packaging safety, it doesn’t inspect every individual package. Instead, it regulates the components that make up food packaging.

Any packaging material that comes into contact with food, known as a food contact substance (FCS), is subject to regulation. These could include:

- Plastics and polymers that form containers and wrappers

- Cardboard and paper materials that are used in boxes and cartons

- Adhesives that seal the packaging

- Dyes and colorants that create branded graphics

- Specialized coating substances that prevent grease and liquid leakage

Under federal law, any food contact substance that qualifies as a food additive must be authorized by the FDA before it can legally enter the U.S. market.

Importantly, not all finished food packaging requires direct FDA approval. As long as manufacturers use substances and materials already authorized by the FDA for their specific intended use, they satisfy the legal requirements.

To support industry compliance, the FDA maintains a public database called Substances Added to Food, which lists nearly 4,000 materials, including those no longer authorized for food contact use.

How to achieve Food Contact Substance Compliance

1. Food Contact Notification Program (FCN)

The Food Contact Notification (FCN) program is the FDA’s primary process for authorizing new uses of food contact substances before they reach the market. Through this pre-market review, manufacturers or sponsors submit scientific data to the FDA demonstrating the safety of the intended use.

The FDA conducts a thorough safety assessment that includes:

- Migration Testing – to analyze how much of the substance might transfer from the packaging into the food.

- Toxicological Review – to ensure that any consumer exposure to harmful substance resulting from this migration is within safe limits.

- Environmental Impact Analysis – to confirm that the substance’s use does not pose significant environmental risks.

It’s important to note that FCNs are specific to the company that submitted the notification and to the specified intended use of the substance. Authorization does not automatically extend to other manufacturers or different applications.

If approved, the substance is added to the public Inventory of Effective Food Contact Notifications. While this is a pre-market process, the FDA may also perform post-market reassessments if new scientific evidence raises safety concerns.

2. Food Additive Regulation

If a food contact substance is classified as a food additive, it must receive FDA authorization before it can be legally marketed or used.

To obtain this approval, a manufacturer or sponsor must submit a food additive petition to the FDA — either to introduce a new food additive or to propose a new use for an existing one.

Once approved, the additive is listed in the relevant FDA regulations, and packaging materials made from these authorized substances are considered compliant. Unlike food contact notifications, food additive approvals are generally not manufacturer-specific and may be used by any company as long as the intended use aligns with the approved conditions.

3. Generally Recognized as Safe (GRAS)

Some food contact substances are classified as Generally Recognized as Safe (GRAS) for their intended use. This designation is based either on a documented history of safe use in food applications or on a consensus of qualified scientific experts that the substance is safe under its intended conditions.

Manufacturers have two options when it comes to GRAS determinations:

- They can self-determine GRAS status without notifying the FDA, as long as the conclusion is well-supported and scientifically sound.

- Alternatively, to ensure transparency and legal compliance, they can choose to submit a GRAS notification to the FDA. This submission outlines the basis for the GRAS determination.

Upon review, the FDA may respond with a “no questions” letter if it agrees with the submitted evidence, or it may raise concerns if additional information is needed.

4. Threshold of Regulation Exemptions

In some cases, the FDA may grant a Threshold of Regulation (TOR) exemption, allowing a food contact substance to be used without being regulated as a food additive.

This exemption is based on scientific evaluation showing that the estimated dietary exposure to the substance is so low and the substance is non-carcinogenic, that it poses no meaningful risk to public health.

Manufacturers or suppliers can request a TOR exemption for a specific substance and its intended conditions of use. If approved, the exemption is recorded in the FDA’s public Threshold of Regulation Exemptions database, which lists all granted exemptions.

FDA Food Labeling Requirements

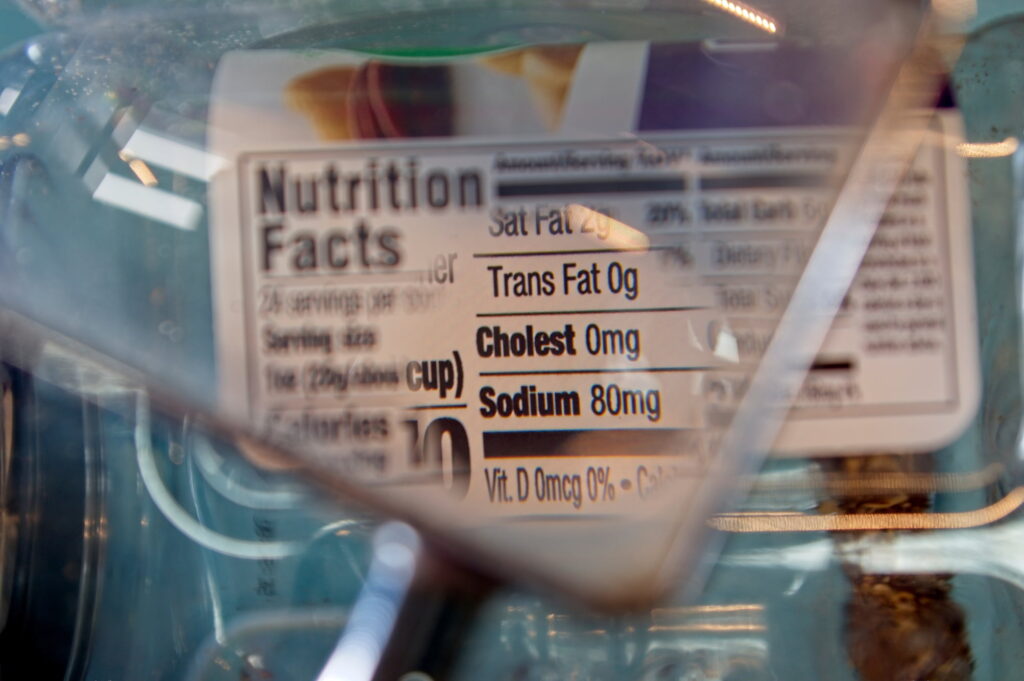

Beyond regulating packaging materials, the FDA also enforces strict food labeling requirements. These ensure consumers receive clear, accurate, and complete information about the food products they purchase.

Most packaged foods sold in the U.S., whether produced domestically or imported, must comply with these packaging requirements.

Food packaging must include these essential labeling:

- Name of the food (legal name, common name, or descriptive name)

- Net quantity (by weight, measure, or count)

- Name and address of the manufacturer, packer, or distributor

- Ingredient list

- Allergen declaration

- Nutrition Facts label (serving size, calories, nutrients, etc.)

To help the food industry stay compliant, the FDA provides comprehensive guidance on what information must be displayed, where it should be placed, and specific formatting requirements such as font size and layout. For details, refer to the FDA Food Labeling Guide.

Other Food Packaging Industry Standards

In addition to mandatory FDA regulations, many food packaging manufacturers pursue voluntary industry certifications to demonstrate a higher level of safety, quality, and compliance. These third-party standards enhance credibility and are often expected by major retailers and global food brands.

One of the most influential frameworks in this space is the Global Food Safety Initiative (GFSI), which establishes benchmarks that harmonize food safety standards worldwide. Earning a FGSI-recognized certification validates a company’s commitment to food safety and quality management.

Below are some of the most widely respected GFSI-benchmarked standards in the food packaging industry:

SQF (Safe Quality Food) Program

The Safe Quality Food (SQF) Program is a globally recognized certification system focused on best practices in food safety and quality across the supply chain. It is administered by the Safe Quality Food Institute (SQFI), a division of the Food Marketing Institute (FMI).

SQF certification outlines clear, industry-driven standards that food processors, manufacturers, and distributors must meet. Earning this certification demonstrates that a company has implemented a comprehensive and robust food safety and quality management system, which is a key requirement for doing business with many leading retailers and brands.

BRCGS Global Standard Packaging Materials

The BRCGS Global Standard for Packaging Materials, developed by the British Retail Consortium, is a widely recognized certification specifically designed for packaging manufacturers.

This standard addresses food safety, hygiene, and quality, and outlines best practices for establishing a robust packaging safety management system.

BRCGS certification is often a mandatory requirement for suppliers doing business in the U.S., Europe, and other global markets, making it a critical credential for packaging companies aiming to operate internationally.

FSSC 22000 (Food Safety System Certification)

FSSC 22000 is a globally recognized scheme that combines the ISO 22000 standard with industry-specific requirements tailored for food packaging manufacturers.

It focuses on the systematic management of food safety hazards throughout the production process, and is compatible with other management systems like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management).

These types of voluntary certifications signal to customers that a packaging manufacturer maintains rigorous food safety systems that go beyond legal regulatory requirements. For food brands looking to build consumer trust and access premium retail markets, partnering with certified suppliers adds a valuable layer of quality assurance.

Navigating Food Safety Compliance with Confidence

Given the critical role of food packaging in protecting public health and maintaining product integrity, it’s essential for food manufacturers to ensure their packaging meets all regulatory requirements and upholds the highest standards of safety and quality.

Feeling overwhelmed by the complexity of federal regulations and industry certifications? PakFactory is here to help. Our team offers professional consultation and tailored packaging solutions to ensure your packaging is compliant, safe, and market-ready—so you can focus on growing your brand with confidence. Contact our specialist today.